Design for manufacture and assembly (DFMA) is used as a basis for concurrent engineering studies to

reduce cost and improve quality through design. The process is a multi disciplinary approach that

can produce game changing results by critically analyzing a design with an eye towards ease of

manufacturability, and ultimately ease of assembly. In order to help our customers meet their DFMA

needs, we created Scitus Engineering, which handles our engineering and DFMA projects.

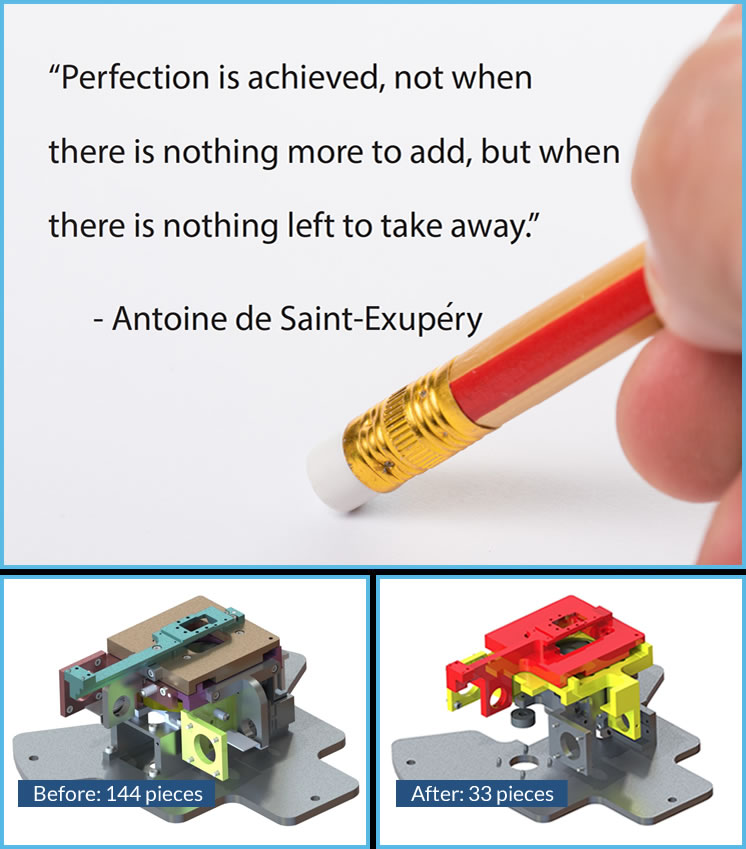

Through understanding the function of components, Scitus is often able to combine multiple parts or

add simple, low cost features that reduce assembly time. They have reduced part counts by as much as

90% on complex projects, resulting in massive cost reductions. Our knowledge and experience with a

wide range of manufacturing modalities allows us to rapidly evaluate projects to determine the best

process for any given stage of a product’s life cycle.

Conducting a DFMA evaluation with Scitus is fast and easy. They use the latest in video conferencing

and screen sharing technologies to reduce the need for time consuming and often expensive travel.

Learn more about

Scitus Engineering, and how their services integrate with CCG’s manufacturing capabilities.